Atlas 618 Pages

(project links at the bottom)

This page will have some projects for the 6" Atlas lathe. There are only a few to start

with, but I have quite a few other pages in the works. They'll be put up when I have time.

I spend most of my time in the shop, and doing all these Taig, Atlas, and Craftsman lathe

pages is just an aside to machine work. If someone likes them, or gets some useful info

out of them, well, good enough.

The Atlas 618 seems to be often confused with another lathe. Maybe that should say,

another lathe is often confused with the Atlas. Many people think that their Craftsman 109

series lathe was made by Atlas. They were not. Atlas made their own lathes, and they

were all capable machines in every respect. Sears contracted with them to make lathes

for the Craftsman brand, same as they did with other tool makers, but Atlas supplied the

same basic lathe for rebranding as they put their own name on.

If you have a Craftsman lathe, look for the model plate on the bed. It will be on one end,

or on the back side of the bed casting. If the prefix starts with 101.xxxx, it is an Atlas.

If prefix starts with 109.xxxx, it was not made by Atlas, but rather the Ann Arbor Co., also

called the AA Co., or Double A.

There are web pages elsewhere on this web site that deal with the Craftsman AA 109

series of metal lathes. If that is what you're looking for, go to the bottom of this page

and click on the Taig link.

The 6" Atlas has a very robust headstock and bed for it's size, with a one inch diameter

spindle having a 17/32" through bore. It has a #2 Morse Taper in the headstock spindle,

and a #1MT in the tailstock. They were equipped with a standard American type carriage

with a rack and pinion drive for regular carriage movements and a leadscrew and halfnut

for threading chores. It will cut most common threads, and the lowest spindle is a very

handy 55 rpm, which makes thread cutting easy.

This is the Atlas 6x18" lathe I use. It's an older model with a 1"-8 spindle nose and plain bronze sleeve

bearings. Newer models have a 1"-10 spindle nose threads, and roller bearings. The headstock castings

varied slightly, but other than the spindle threads and bearing types, they all look very similar. There is

a MK II production that looked completely different with a square headstock and more angular castings.

The web site http://www.lathes.co.uk/atlas6inch/ has quite a section on these lathes, and is worth checking out.

The following thumbs open to some project pages.

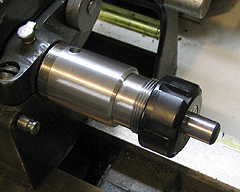

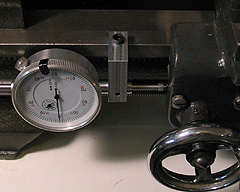

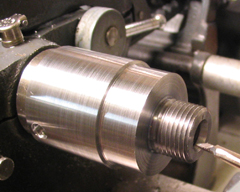

Making an ER Collet Closer Chuck For the Atlas 618  Removing the back gear on your 6" Atlas For cleaning and general maintenance.  A dial indicator mount for the lathe bed. For keeping track of your Atlas carriage.  A spindle adapter for the Atlas 618 For different chuck mounting, collet chucks, and like that. |

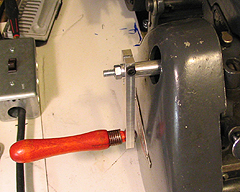

Removing the spindle on your 6" Atlas. For replacing belt, thrust bearing service, bull gear bushings, or replacing the main spindle bearings.  A spindle crank. For slow speed thread cutting. Great for cutting metric threads on your Atlas.  Cutting a new Tumbler Gear for the Atlas |

More Taig Lathe & Mill Projects

deansphotographica.com

(home page)

Copyright 1998-2012 Dean Williams