A Flex Wrench

(for slippery round things...)

Flex wrenches are handy for round threaded pieces that otherwise have no surface

to grip for tightening or removal. I use these mainly for camera work. Older cameras

often have knobs and dials that have no obvious way of removing them. They have

been threaded onto the camera at the factory by means of a friction driver, and are

a stinker to remove without a tool that will grip a smooth round surface.

The flex wrench works much like a pipe wrench, but it has no jaws to mar a surface.

Instead, it relies on the entire surface of the wrench being in contact with the part

you want to remove. This is one I made up for a job recently. As often happens, I

needed the tool right away, so made it with a minimum of shine and polish work. I've

made a few of these over the last few years. This is the first one I've made on the

Taig mill. I used to make them on the Taig lathe.

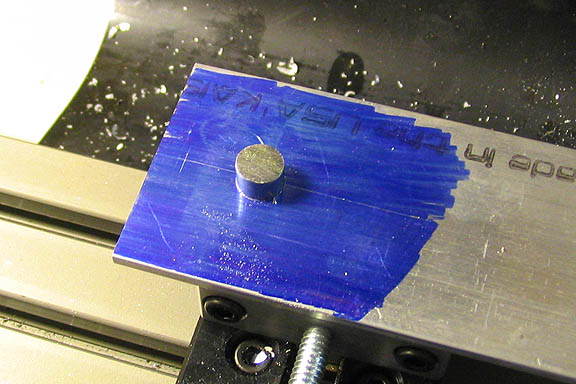

Starting with a piece of 1/8" x 2" aluminum, a 3/8" hole is drilled in one end. The hole

is drilled centered in the stock and 1/4" plus half the diameter of the size needed for the

wrench. Then, if you don't have a rotary table, you can mill the radius on the end of the

wrench by using a 3/8" piece of round stock as a pivot.

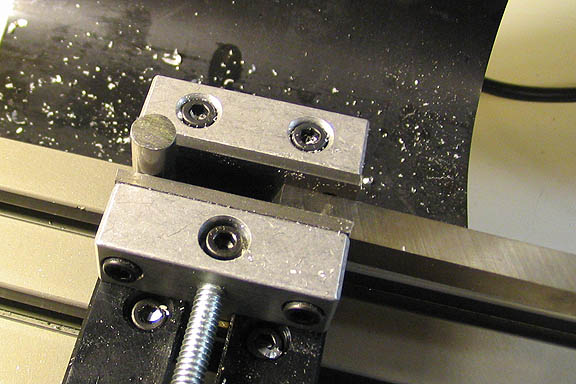

The round stock used as a pivot is positioned in the mill vice as shown above.

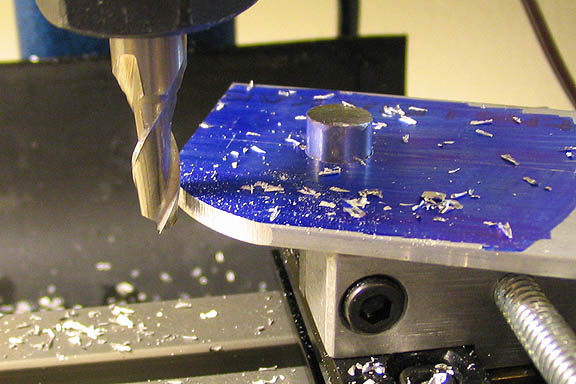

Then, the piece of aluminum stock is rotated on the piece of round stock to cut the

radius. When using this method, you have to be very sure to up mill only. Always move

the work piece into the cutting edge of the rotating mill. If you down mill, the piece can be

pulled into the mill and make a mess. This method works for steel work pieces too, but

you must take light cuts. A sharp end mill is mandatory. Keep a firm grip on the piece as

it is rotated. Go slow.

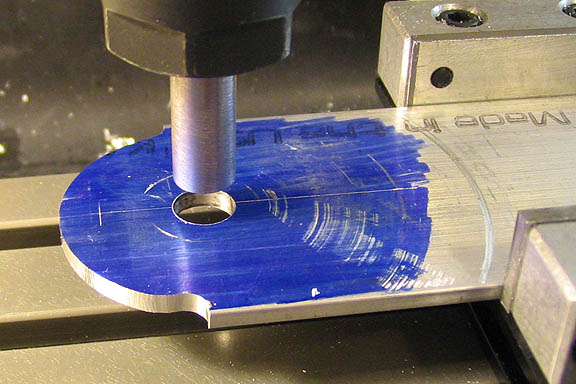

Once the radius is milled on the end of the work piece, center can be located using the same

piece of round stock that was used as a pivot. Mount the round stock in the spindle and

center it in the drilled hole in the work piece.

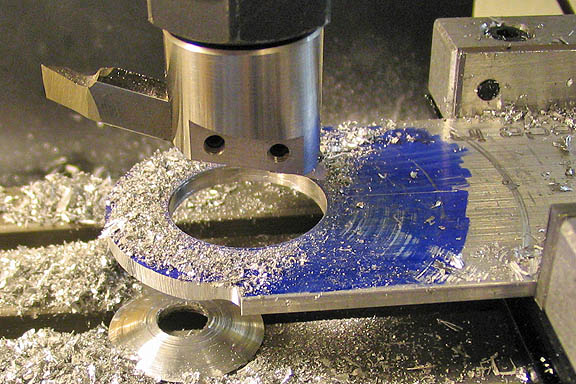

Now a larger hole is cut. In this shot, a fly cutter is being used with a HSS bit. It's a big

cut since the tool tip cuts away a lot of material before the "hole" falls out, so the slowest

spindle speed was used. Then the bit is repositioned in the fly cutter a few times until

the proper sized finished hole is cut.

A boring head would be a more proper tool for this job, but I haven't made one yet. That's

another project. The fly cutter will do fine, though adjusting the bit for an exact

size hole takes more time.

Here's the hole finished to the proper size needed for this wrench. The rest of the job is

simple straight milling so I won't show it here.

The slot in the finished wrench needs to be wider toward the ends of the handle, as can

be seen in this shot. If the wrench to be made is very small, like 1/2", the slot leading up

to the hole can be quite narrow, like 1/8". The narrower slot in the wrench here is 3/8" and

the wider section is .575". The overall length of this wrench is six inches. If you were

making a wrench for a 1/2" diameter object, the OAL should be around three inches to keep

from putting too much pressure on what you're trying to loosen, (like thin wall tubing, for

instance).

These wrenches have a pretty narrow range for the given hole size. The one in this

particular wrench happens to be 1.225", and it will fit on round shafts, dials, etc., that

are from about 1.220" to 1.230", and maybe a little more or less. Not much though. If

you try to use it on something too small or large, it won't grip well. If you need to loosen a

lot of different sized round things, you will need to make a number of wrenches.

More Taig lathe projects

deansphotographica.com

(home page)

Copyright Dean Williams