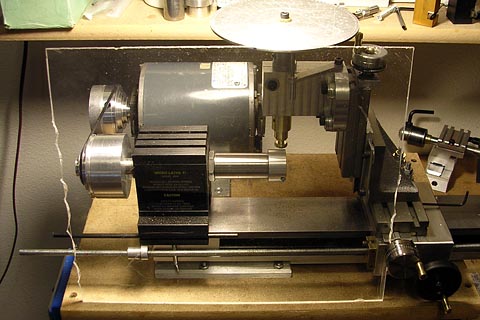

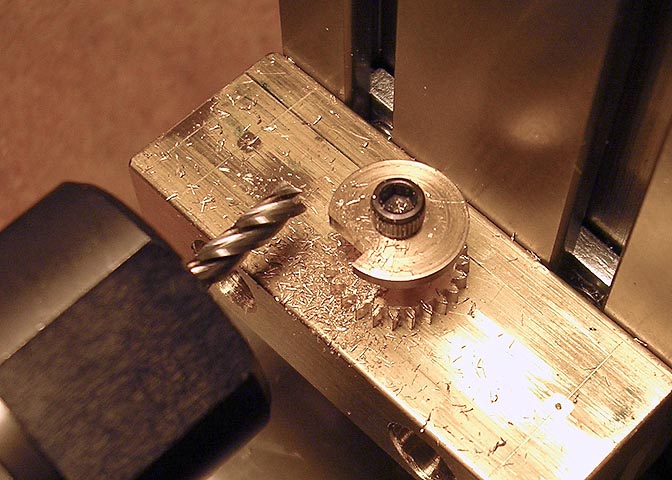

This is the setup, ready for gear cutting. The lathe is a Taig. They're small, really sturdy

machines. The round thing at the top of the shot is an indexing disc. I made it a few years

back. It's for indexing spaces at precise increments, like the spaces between gear teeth.

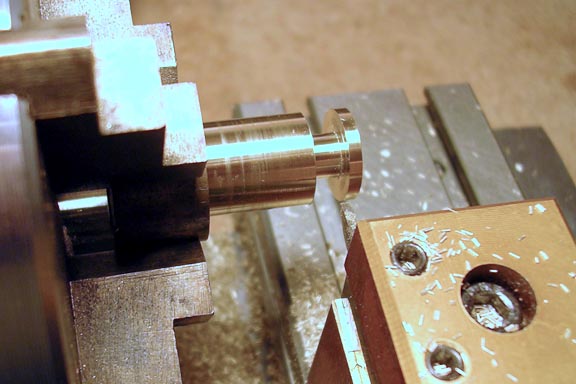

The first step in gear cutting is to have a blank the proper diameter for the gear. This is a piece

of brass, turned up to the proper diameter for the size of the gear.

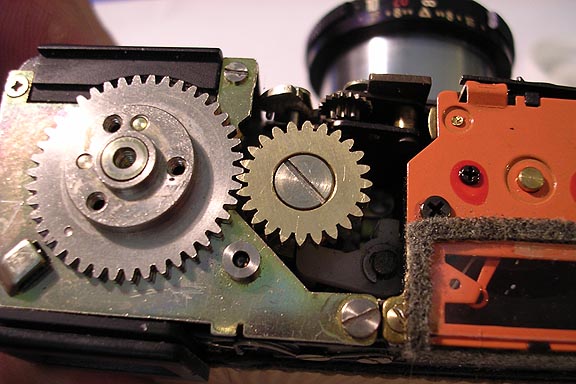

The Rollei 35 gear has a second half at the end of a short shaft that engages a ratchet in the camera.

Once the two diameters are turned up, the piece is parted off.

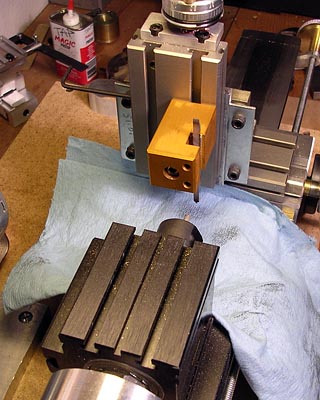

Next, I need a cutter with the proper profile to cut the gear teeth.

There are dozens of gear cutter profiles. I need to make a cutter

for this specific gear size.

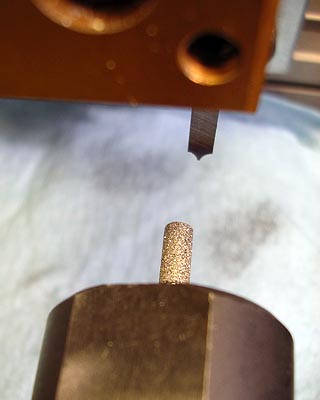

The profile is cut with a diamond burr of the correct diameter

to produce the gear tooth profile.

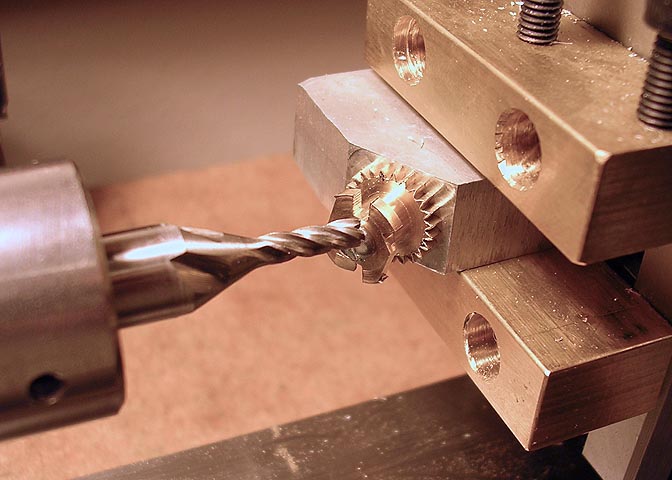

The gear blank is attached to the indexer, and the cutter is mounted in an arbor

in the end of the lathe head. Then each tooth is cut out on the blank.

You can see what goes on in this shot. Just about to cut the last tooth.

Here, the gear part is done, but there's more to do on the other end.

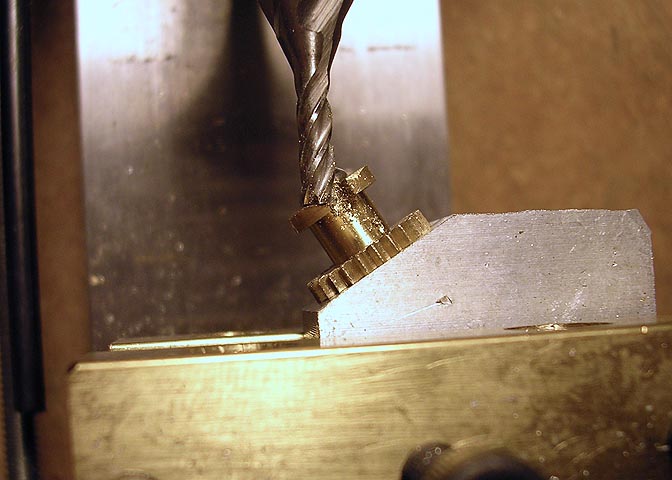

There are a number of cutouts and angles on the back side of the gear shaft. I made a simple setup

to hold the gear for milling. If I want to make more of these, I'm gonna make some jigs.

This is the first cut of many.

There are two angled bevel cuts on the bottom to allow the gear to turn backwards after cocking the camera,

returning the cocking lever to it's rest position. So I had to make a jig for this. All other cuts have been made

in this shot, except for the two angled cuts.

Cutting the bevel, and after deburring, that's it.

And that's it. Pardon the shavings/dust.

And this is where it goes.

Home