Clock making...

I am not a clock maker. I've done some fairly routine clock repair work, but it's not my

regular job. By "fairly routine" I mean I replace pivots, lanterns and wheels in a clock

that may have been neglected for some years and needs a little fixing up.

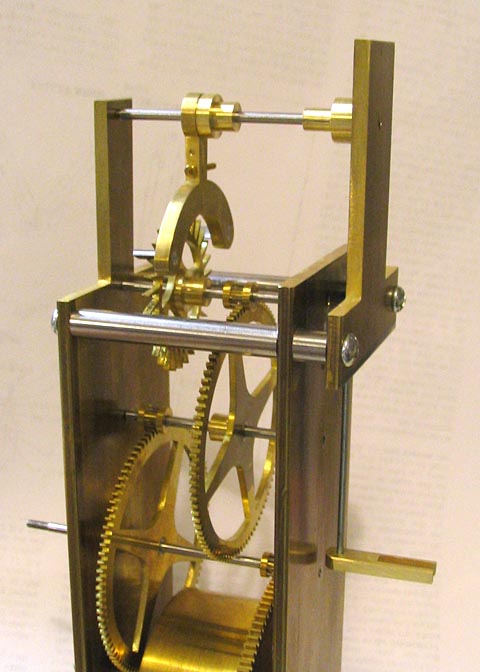

This clock making project is an ongoing endeavor. I started on it in September of 2008,

I think, and have been pecking away at it on and off for months. I have had it in running

condition since December or January, but it is far from complete. At the moment, it sits

on a shelf in my shop, no dial or hands, and the motion works not yet mounted, but the

movement itself has run for months now with nary a missed beat.

This isn't an instruction article. It's just a collection of pictures I took while building

the clock to its' present state. The clock was designed by Elliot Isaacs, and construction article

can be found on the mlhorology group, (Horology for Mini Lathes group). You may have to join

the group to see the article and drawings in the files area, but joining just requires signing up

for a free Yahoo account.

The Wheels.

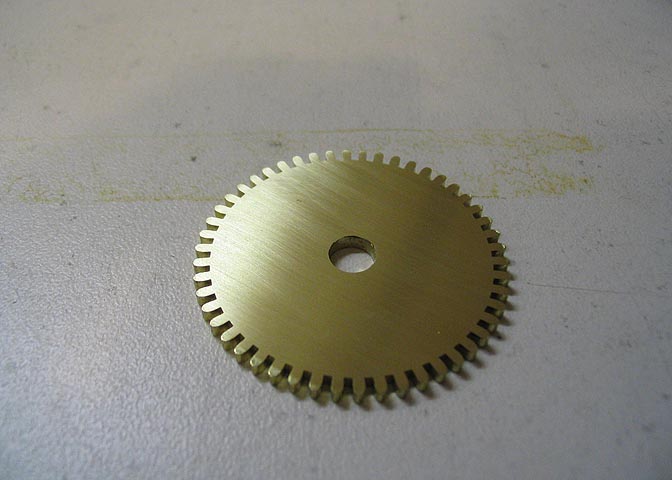

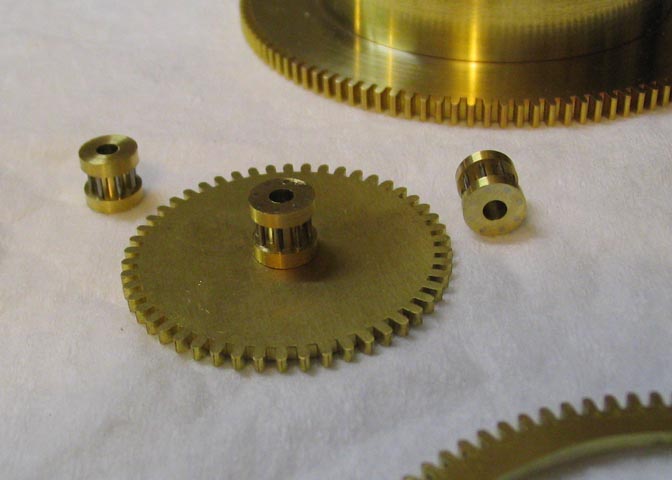

Wheel blanks cut out.

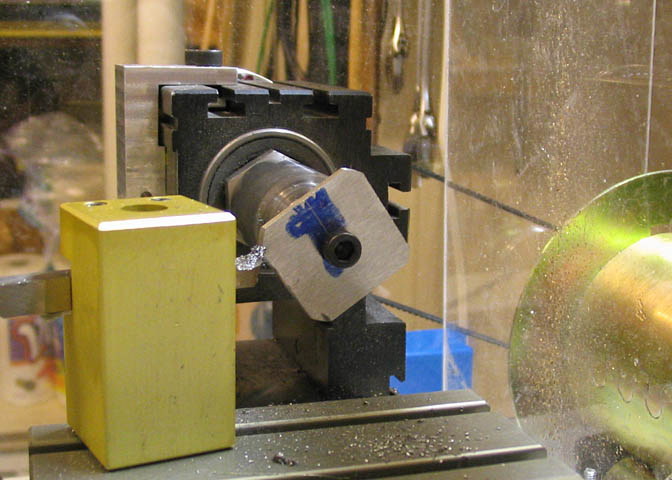

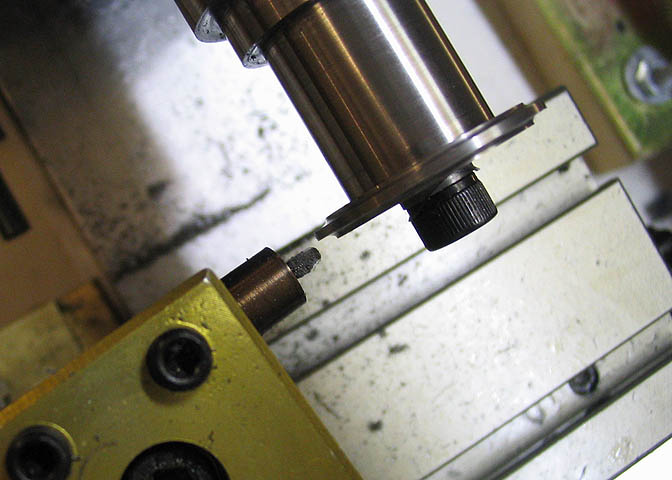

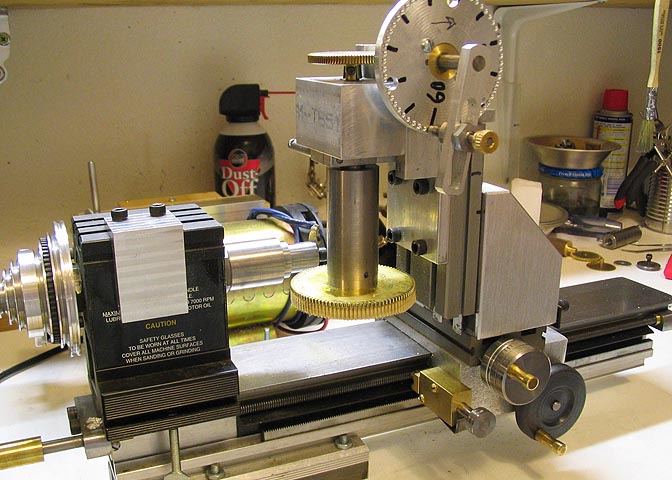

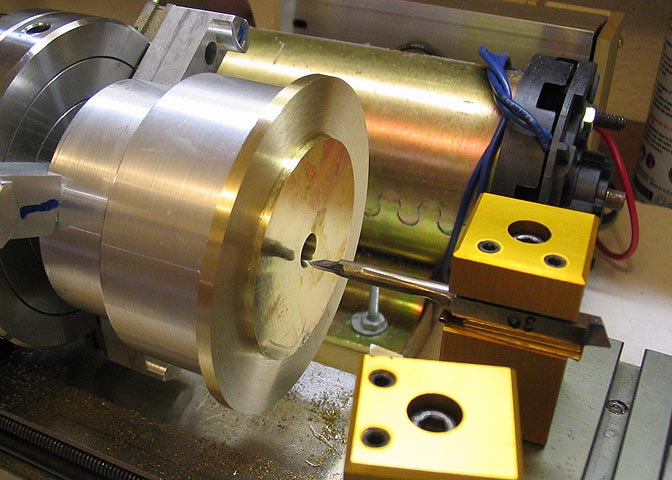

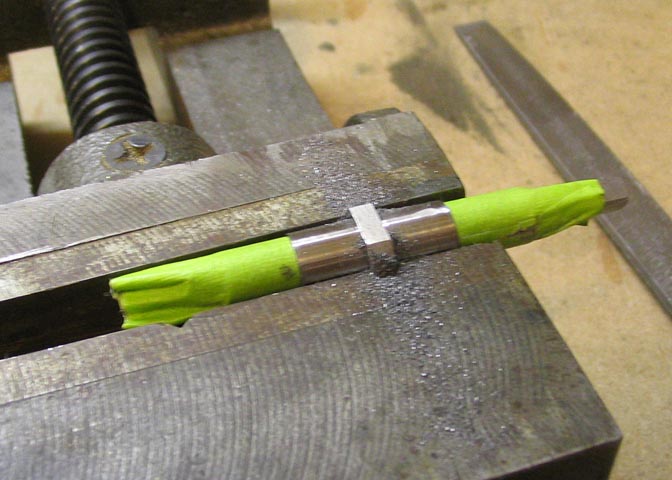

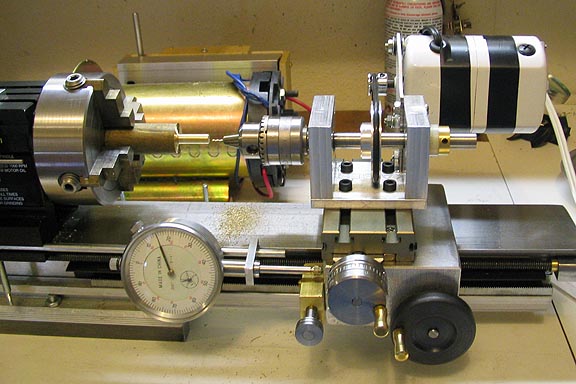

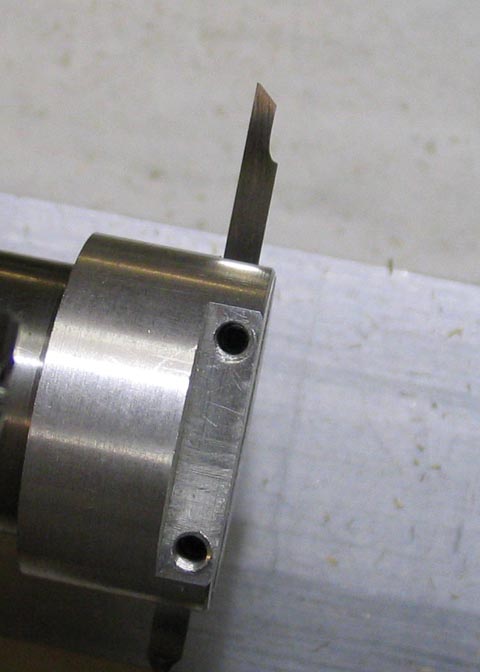

Above, and next four pictures, making the wheel tooth cutter.

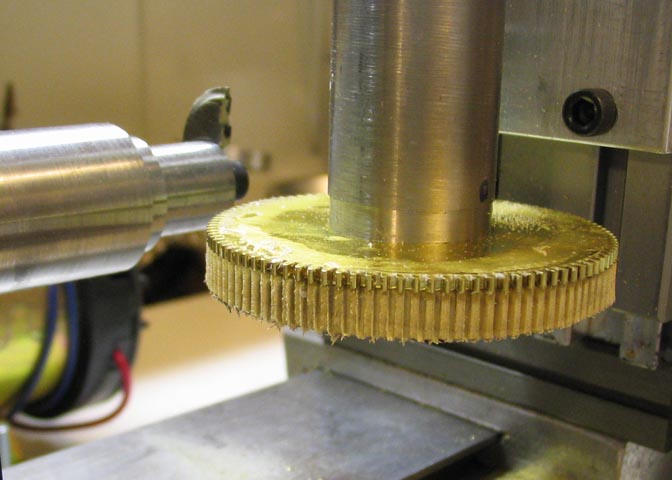

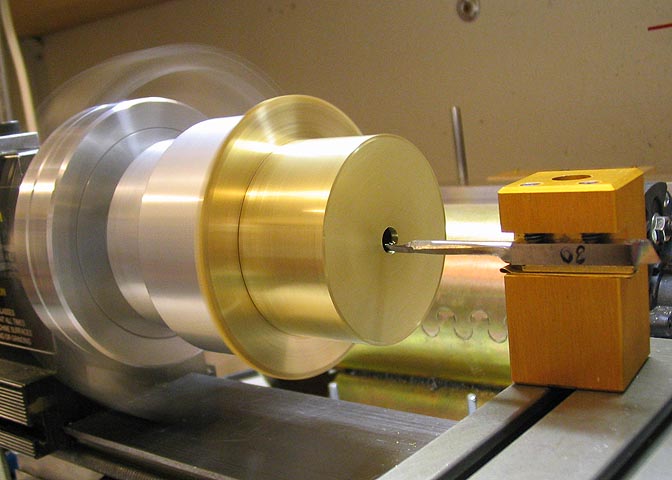

Cutting a wheel.

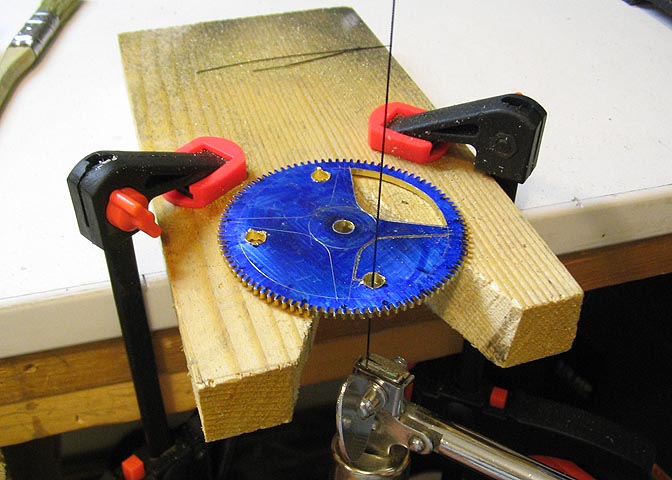

A wooden blank is used to keep the wheel from bending.

Crossing out a wheel. This takes me forever. I've seen a real

clock maker do it in about 10 minutes. All four sections.

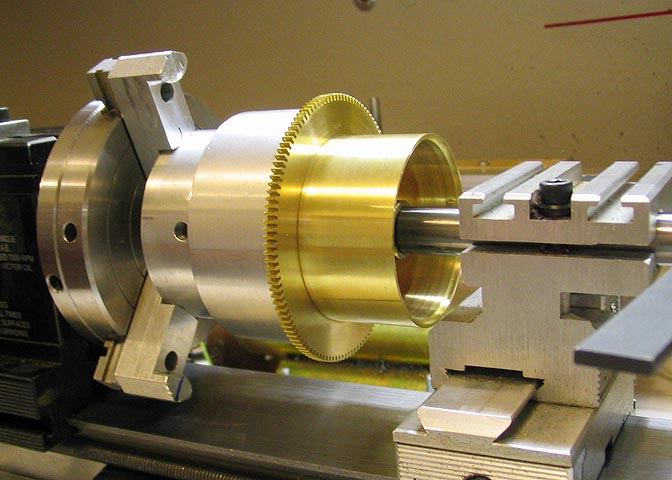

The Great Wheel and Barrel

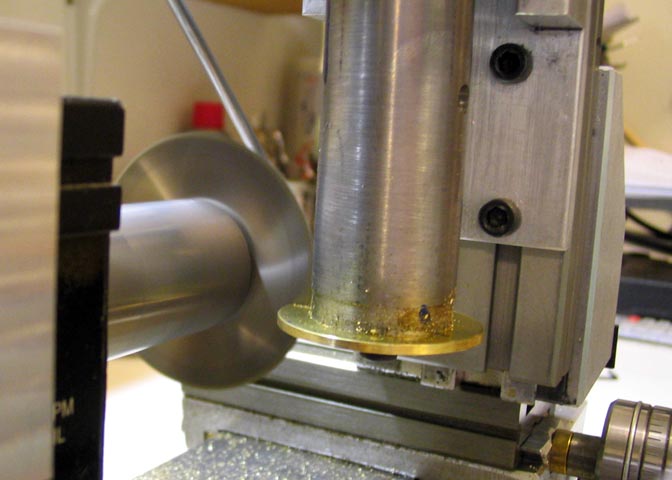

The great wheel blank, held to an arbor with super glue.

The barrel is soldered on, trued, and a recess cut for the barrel cap.

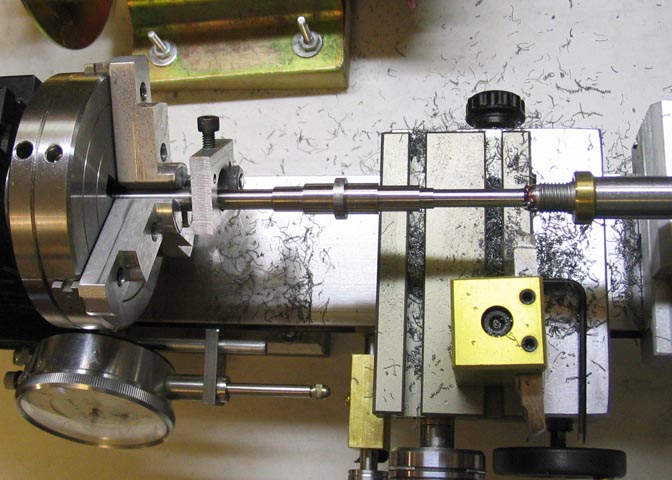

This is the great wheel/barrel arbor.

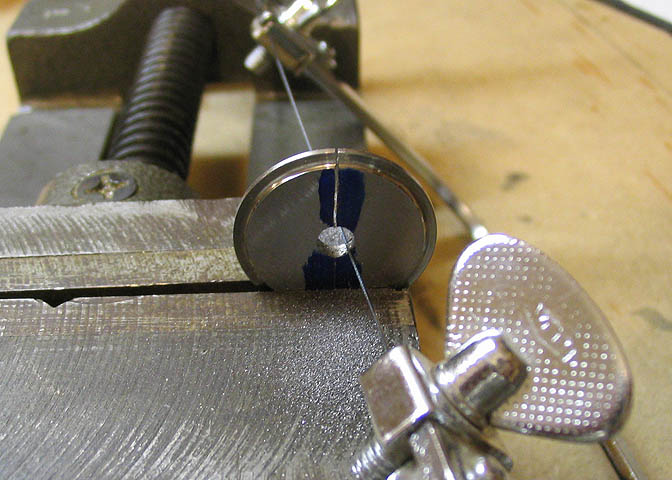

Filing the spring hook on the barrel arbor.

The Lanterns

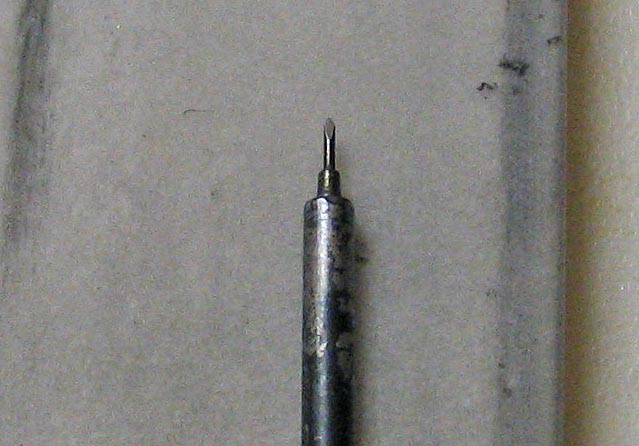

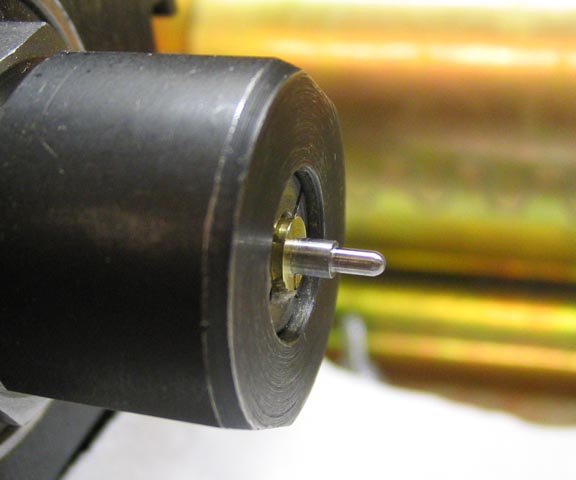

I made a pivot drill on my WW lathe.

It's a simple two bladed drill, sharpened on a stone.

Ratchet and Click

The ratchet cutter. A simple grinding job on HSS.

Cutting the ratchet.

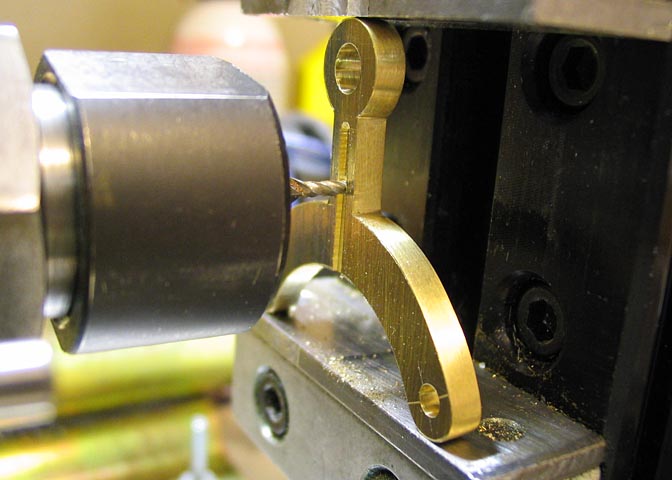

This click is far from finished!

The Brocot Escape

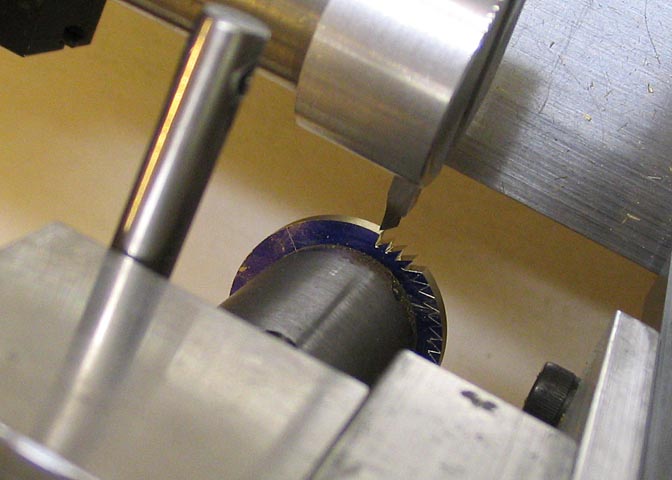

The teeth on the escape wheel are cut with a slitting saw.

The Brocot escape marked out.

Cut out.

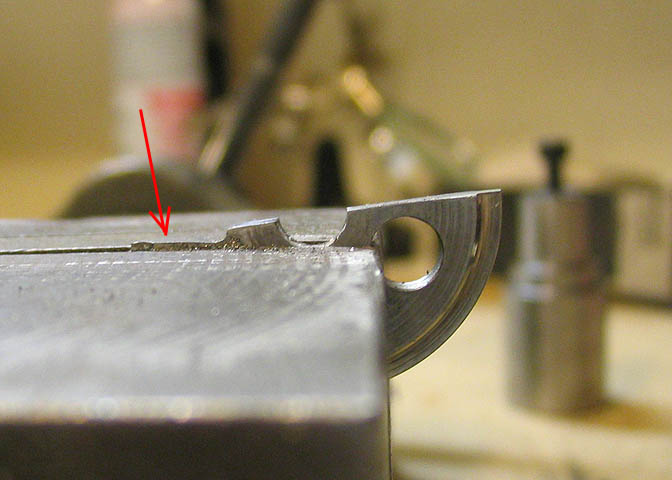

After filing the edges, the slot is milled.

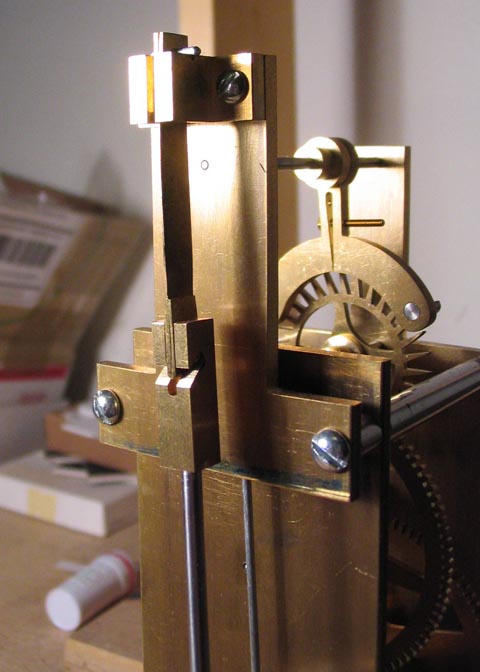

The Backcock

Misc.

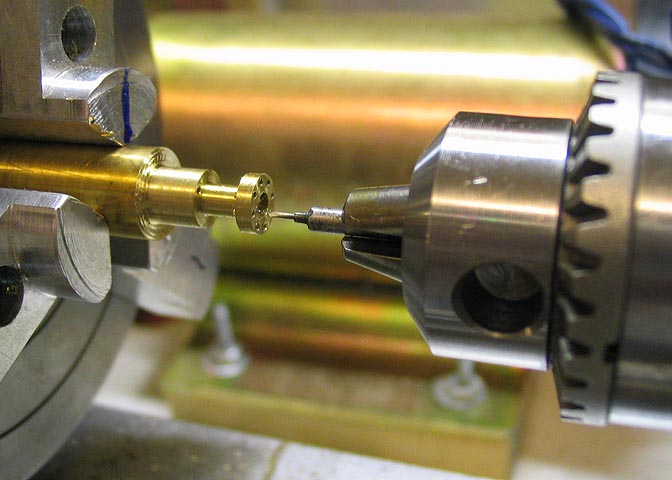

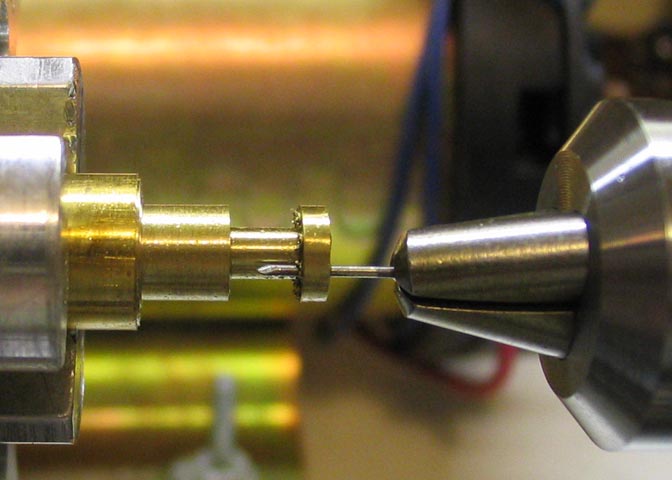

Making pivots.

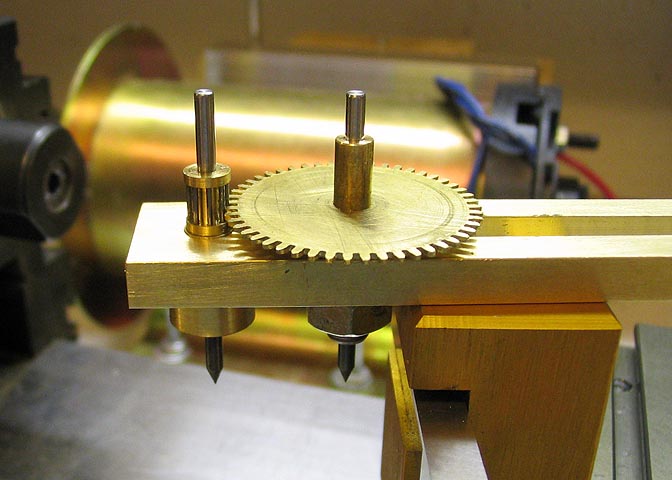

A simple wheel depthing tool.

More Taig Lathe & Mill Projects

deansphotographica.com

(home page)

Copyright Dean Williams