An Improved Tail Stock Ram for the Craftsman 109

The taper in the original ram on my 109 is pretty gouged up, and I also

don't have an adapter to use a drill chuck in the ram. They are tiny #0 MT

jobs, and I'd rather just have a solid ram that is tapered and threaded

on the end for chucks and turning between centers.

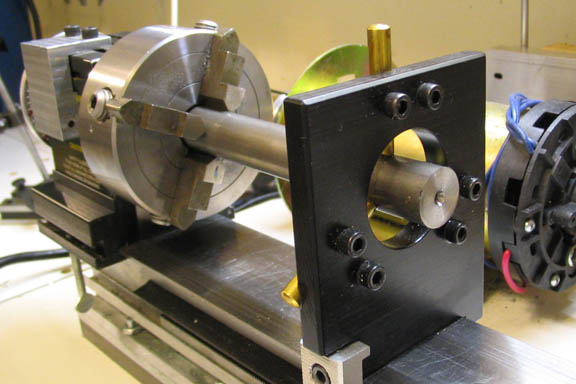

This tail stock ram is similar to the one Taig uses on their lathes, and one I'm

used to since I have one of their machines too.

All the steps are simple turning jobs.

First step is to drill center holes in the ends of a piece of stock so a center can be

used for accurate turning of a long work piece. I started out with a 7" long piece

of 3/4" dia 12L14. I did this step in the Taig lathe, since I have no way of

mounting a drill chuck in the Craftsman (yet). The center hole could also be

drilled in a drill press after using a center finding square to find center of the piece.

Then the piece is moved to the 109 and the long end of the ram is roughed out.

There will be a chuck register on the ram, and the end behind the

register is 3 1/2" long, finished length. This portion of the ram is turned down

to .500 diameter.

Once the long end is finished, the piece is flipped end for end and dialed in. Then the

short end can be turned down. I left the register ring at .2" thick, and the portion to

be threaded at 1 1/2" long at this point. It will be shortened later when the taper is cut.

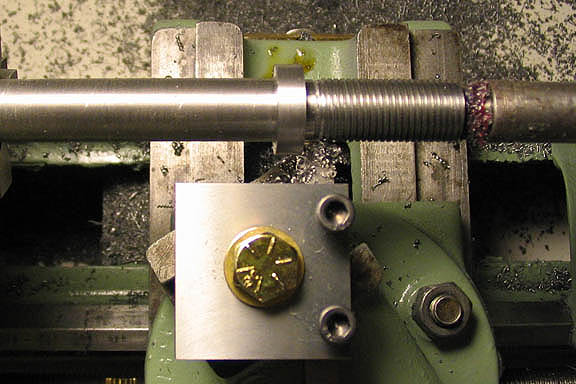

Once the diameter of the short end is finished, it's threaded for 1/2-20, (or for what

ever thread you would like, depending on the drill chuck you use).

After threading to nearly the complete depth, a die is run over the threads to finish them off.

They could be threaded just using the lead screw to cut them, but running the die over them

just before final cut depth is reached makes a nice finish on the threads.

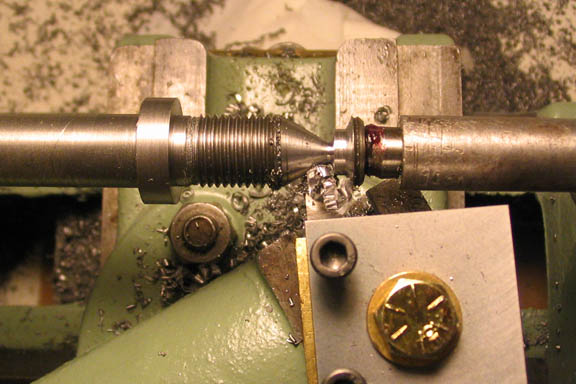

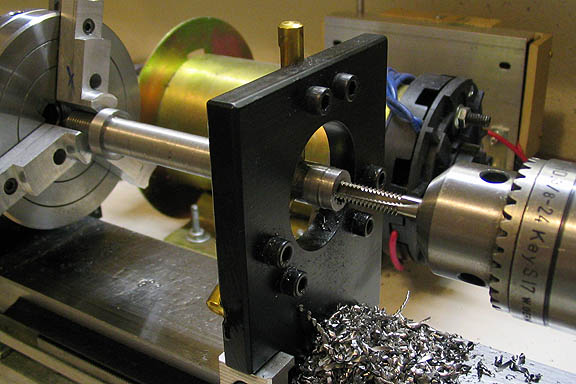

The last step is to cut the taper and cut off the waste at the end of the shaft. I started

the large end of the taper at 3/4" from the register face and turned it to get down to what is seen

in this picture. The last bit is cut off with a hack saw. You probably don't want to cut

it to the completed length while it's got pressure from the tail stock center against it. If

you do, when you get to the last few thous that are holding the piece together, it will probably

separate and the part will ride up over the cutting edge of the tool, spoiling the job.

The taper was finished after backing off the tail stock and took many light cuts to get it

down to finished length. It's hanging out of the head stock chuck nearly four inches, so a

light touch is needed prevent chatter. Lock any gibs not in use.

The correct overall length was determined by threading the drill chuck onto the tapered end.

When the drill chuck seated down nicely on the register, it was done. The drill chuck I'm

going to use has a small hole completely through its' body, and that allows the tapered end

a place to protrude into it a bit while still leaving plenty of threads to attach the chuck.

The chuck I'm using also has a two thread rebate just inside the hole in the back of the

chuck to allow it to seat. If you use a chuck without a rebate, you will need to cut down

the last couple of threads next to the register to allow the chuck to seat flush.

The next thing is to drill and tap the long end for a left hand thread. I chose

1/4-20 LH since that's what I had handy. The thread of the original piece was 5/16-24,

which is not very good for calculating ram travel if you're trying to do it in your head. At

some point I'll add a mic dial to the end of the ram screw, and it will be easy to determine

drilling depths, since the 20 pitch of the new screw gives .050" per turn.

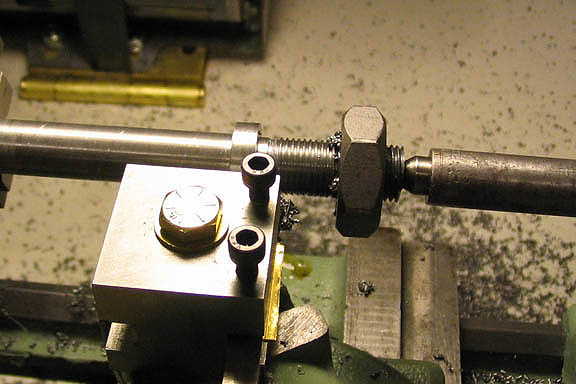

The end of the ram screw is made of a built up piece, one end of which will thread into

the ram, and the other end will take the hand crank on the end of the tail stock. A small

stub is turned to a similar shape and length of the original, then flipped in the chuck and

drilled and tapped for 1/4-20 LH. Dimensions of the piece are as follows;

Small end, .312" dia for a length of .875".

Large end, .440" dia for a length of .250".

Tap 1/4-20 LH 3/4" deep in large end.

This is the finished stub, and a piece of 1/4-20 LH threaded rod has been screwed in and pinned.

The pin goes in the small hole, which can be at any convenient location in the stub where it will go

through the threaded rod inside the stub. The larger hole is for the pin that holds the crank to the

ram screw. The ram, screw, and the little stub must be assembled and inserted into the tail stock

to find the location of the larger hole. Once it's in the tail stock, the handle is slipped over the end

and a transfer punch used to mark the hole. If you have the original pin, it's tapered. Measure

it's diameter about mid point and choose a drill bit of that diameter for the hole and the taper pin

should work as it's intended when put to use.

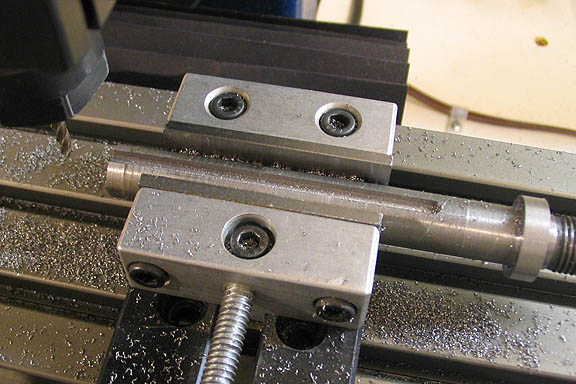

The last step is to mill the slot in the ram. For this lathe, it's a handy 1/8" wide

and .062 deep. Make it about three inches long and it will be fine.

Clean it up and it's ready to go.

Finished.

I just happened to have a brand new Rohm chuck in 1/2-20 mount that was needing to be used.

Until I got the 109 lathe, I had nothing to use it with. Now it has a home.

The new ram sticks out of the tail stock about 1/2" farther than the stock original,

which is how I wanted it. It gives just that little bit of extra length for holding a work

piece that is being turned between centers.

Back to Craftsman 109 Projects

More Taig Lathe & Mill Projects

deansphotographica.com

(home page)

Copyright Dean Williams