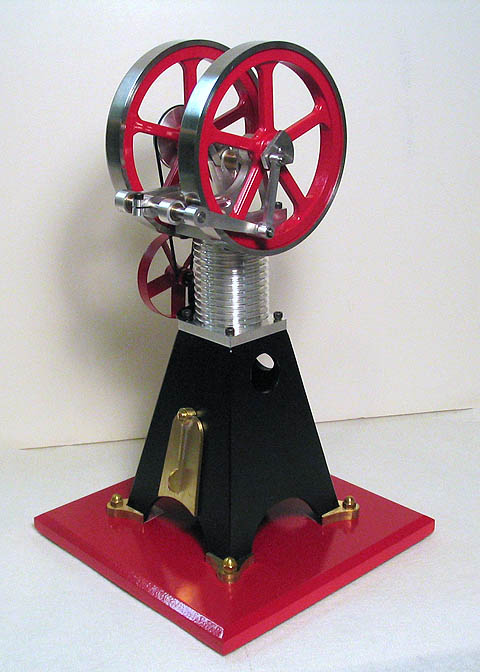

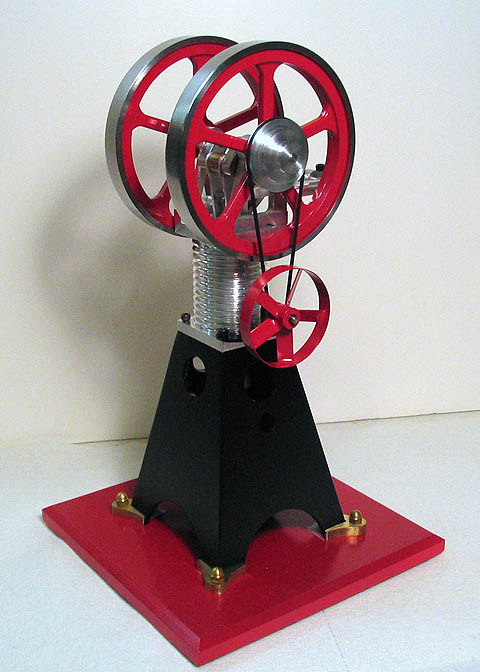

Duplex Vacuum Engine

This is a reproduction of the Duplex Vacuum engine that was produced sometime

during the period of 1900-1920. As descriptions go, the name is somewhat misleading.

The engine type is a Heinrici Stirling variation, but the name might make one think it is

some type of vacuum engine. Since the originals of this model were made by a company

called the Duplex Vacuum Company, who made vacuum cleaners, this particular version

is named for that company.

The person responsible for the design of the engine was one of the Heinrici brothers.

There were two of them involved, and I don't know which designed the prototype. They

were produced in a fair number, and examples are still seen today.

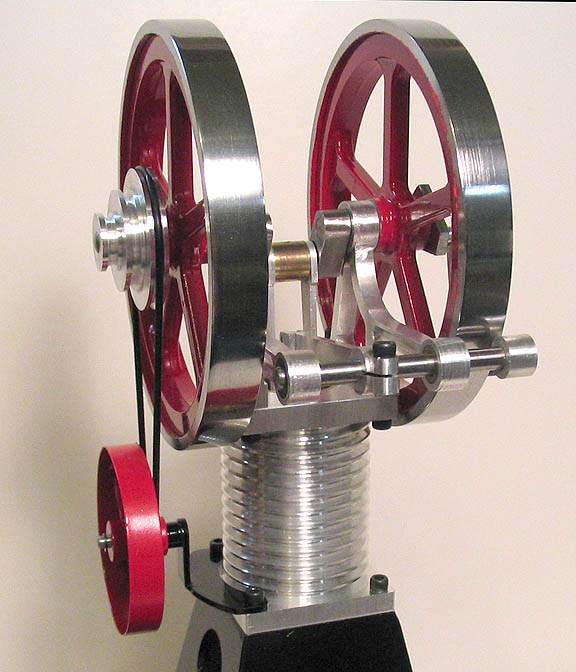

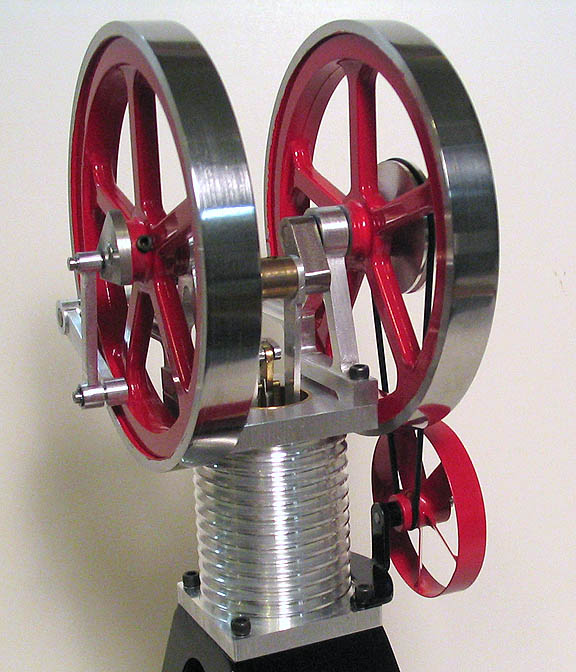

I built this particular one using a Taig manual milling machine for all the milled parts,

and the turned parts were made using Taig and Atlas manual lathes. No CNC machines.

The power piston is made of graphite, and power cylinder is aluminum sleeved with 360 brass.

The displacer end cylinder is 416 stainless, and the displacer piston is aluminum.

The base is 1018 CRS made in four pieces and silver brazed together.

The crankshaft runs in small ball bearings.

The fan and pulley on the one side of the engine were not part of the prints, but I thought the

fan would help cool the finned power cylinder.

Prints are from Jerry Howell. He's passed on now, but his family still run the business as he did,

and sell his complete product line of prints and other things for model engine builders. Prints for

this engine are available on his web site.

I spent three months on the construction, (part time!), coming to about 250 hours total.

Here is a short video of the engine running. The camera work is a bit jumpy as I was changing

the fan belt as the engine was running in order to slow down the fan a bit. After the fire is

extinguished, the engine continues to run for some time on the residual heat in the displacer

end of the cylinder. The heat is provided by a very small propane burner inside the firebox. That

burner is also featured on the main page, linked at the bottom of this page, and was built, again,

from Jerry Howell plans.

It will run much faster if the flame is turned up on the burner, but then it starts getting hot

fairly fast. Once it gets just so hot, it will start to slow down because the fins on the cylinder

cannot dissipate heat fast enough to run efficiently.

Thanks for checking it out.

More Taig Lathe & Mill Projects

deansphotographica.com

(home page)

Copyright 1998-2010 Dean Williams